Introduction

In the realm of woodworking and construction, precision is paramount, and mastering the technique of saw cuts can make all the difference between a flawless masterpiece and a botched project. Whether you’re a seasoned carpenter or a DIY enthusiast, understanding the nuances of saw cuts is essential for achieving professional-grade results. This comprehensive guide will delve into the intricacies of saw cuts, covering everything from essential terminology to advanced techniques.

Understanding Saw Cuts

The Basics of Saw Cuts

Saw cuts form the foundation of woodworking, encompassing a variety of techniques used to divide materials such as wood, metal, or plastic. From simple straight cuts to intricate curves, each type of saw cut serves a distinct purpose in shaping and assembling materials.

Types of Saw Cuts

1. Crosscuts

Crosscuts involve cutting across the grain of the wood, producing perpendicular slices that are ideal for creating uniform pieces and trimming lumber to size.

2. Rip Cuts

Rip cuts, on the other hand, follow the grain of the wood, resulting in long, parallel cuts that are perfect for ripping boards and creating custom widths.

3. Miter Cuts

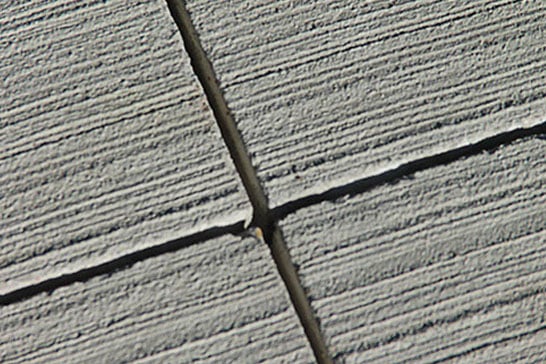

Miter cuts are angled cuts made across the width of the material, commonly used for creating precise joints and framing corners.

4. Bevel Cuts

Bevel cuts involve tilting the blade of the saw to create angled edges, adding versatility to woodworking projects and allowing for intricate designs.

Advanced Sawing Techniques

1. Dado Cuts

Dado cuts involve removing a channel or groove from the surface of the material, commonly used for joining pieces together or creating decorative accents.

2. Scroll Cuts

Scroll cuts are intricate curved cuts made with a scroll saw, allowing for detailed designs and artistic flourishes in woodworking projects.

3. Compound Cuts

Compound cuts combine both miter and bevel angles, resulting in complex shapes and joints commonly found in furniture making and cabinetry.

Mastering Precision

Choosing the Right Saw

Selecting the appropriate saw for your project is crucial for achieving precise cuts. From circular saws to table saws, each type of saw offers unique features and benefits suited to different applications.

Proper Technique and Safety Measures

Achieving precision in saw cuts requires not only the right tools but also proper technique and safety precautions. Always wear protective gear, maintain a stable work surface, and follow manufacturer guidelines for optimal results and safety.

Maintaining Sharp Blades

Sharp blades are essential for clean and accurate cuts. Regularly inspect and sharpen your saw blades to ensure peak performance and minimize the risk of tear-out or splintering.

Frequently Asked Questions (FAQs)

- What safety precautions should I take when performing saw cuts?

Safety should always be a top priority when working with power tools. Wear appropriate protective gear, including safety glasses and hearing protection, and ensure that your work area is well-ventilated and free of clutter. - How do I prevent tear-out when making saw cuts?

To minimize tear-out, use a sharp blade and apply masking tape along the cut line before sawing. This helps support the wood fibers and reduces splintering. - Can I use a hand saw instead of power tools for saw cuts?

While hand saws offer greater control and precision in certain situations, power tools such as circular saws and jigsaws are more efficient for larger projects and repetitive cuts. - What is the difference between a crosscut and a rip cut?

Crosscuts are made across the grain of the wood, while rip cuts follow the grain. Each type of cut serves different purposes and requires specific techniques and tools. - How do I achieve precise angles in miter cuts?

To ensure accuracy in miter cuts, use a miter saw with adjustable angles and make test cuts on scrap material before cutting your project pieces. - Can I use a circular saw for bevel cuts?

Yes, circular saws equipped with tilting bases can make bevel cuts by adjusting the angle of the blade.

Conclusion

Mastering the art of saw cuts is a fundamental skill for anyone involved in woodworking or construction. By understanding the different types of cuts, choosing the right tools, and practicing proper technique, you can achieve precision and excellence in your projects. Whether you’re building furniture, framing a house, or tackling a DIY endeavor, saw cuts are the cornerstone of craftsmanship and creativity.