Introduction:

Light frame construction is a widely employed building method that utilizes lightweight materials such as wood or steel for framing. This technique is prevalent in residential and commercial construction due to its cost-effectiveness, versatility, and efficiency. In this article, we will delve into the key aspects of light frame construction, exploring its history, materials used, construction process, advantages, and challenges.

Historical Evolution:

Light frame construction has a rich history dating back to ancient times when timber framing was commonly used. However, the modern form we recognize today gained prominence in the United States during the 19th century with the advent of balloon framing. Over the years, innovations in materials and construction techniques have contributed to the evolution of light frame construction.

Materials Used:

Wood: One of the primary materials in light frame construction, wood offers a unique combination of strength, affordability, and sustainability. Engineered wood products, such as laminated veneer lumber (LVL) and oriented strand board (OSB), have become integral components in modern light frame structures.

Steel: In commercial and industrial settings, light gauge steel framing is a popular alternative. Steel provides excellent strength and durability while allowing for design flexibility. It is resistant to pests and fire, making it a preferred choice in specific construction scenarios.

Construction Process:

Design and Planning: The construction process begins with meticulous design and planning, considering factors such as load-bearing requirements, architectural aesthetics, and local building codes.

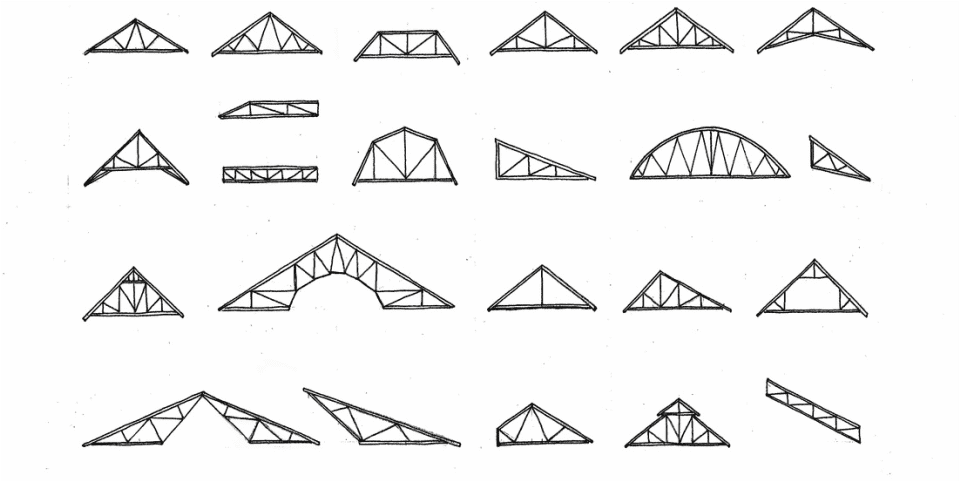

Framing: The framing stage involves the assembly of the skeletal structure using prefabricated components. The use of standardized framing elements enhances construction speed and accuracy.

Sheathing and Insulation:

Once the frame is in place, sheathing materials like plywood or OSB are applied for structural support. Insulation is then added to enhance energy efficiency and provide thermal comfort.

Exterior Finishing: The exterior is finished with materials such as siding or stucco, providing protection from the elements and contributing to the building’s aesthetic appeal.

Advantages: a. Cost-Effective:

Light frame construction is generally more affordable than other methods, making it accessible for various construction projects.

Speed of Construction: The prefabricated nature of light frame components allows for quicker construction timelines, reducing overall project duration.

Design Flexibility: Architects and builders appreciate the versatility of light frame construction, enabling diverse architectural styles and layouts.

Challenges:

Fire Risk: Wood, a common material in light frame construction, is susceptible to fire. Adequate fire-resistant measures must be incorporated to mitigate this risk.

Limited Span and Height: Light frame construction may have limitations in span and height compared to other construction methods, necessitating additional structural considerations for larger buildings.

Conclusion:

Light frame construction has become a cornerstone in the building industry, offering an efficient and cost-effective solution for a wide range of structures. As technology advances, innovations in materials and construction techniques will likely continue to shape the landscape of light frame construction, ensuring its continued relevance in the ever-evolving field of architecture and construction.